This article provides a comprehensive overview of the principles and technologies that enable ships to float and stay afloat, explained through Archimedes’ principle. It also explores the applications of Bernoulli’s principle in the context of ships and marine engineering, particularly in the design of hulls and sails, as well as understanding how sails generate lift.

How Ships Float And Don’t Sink?

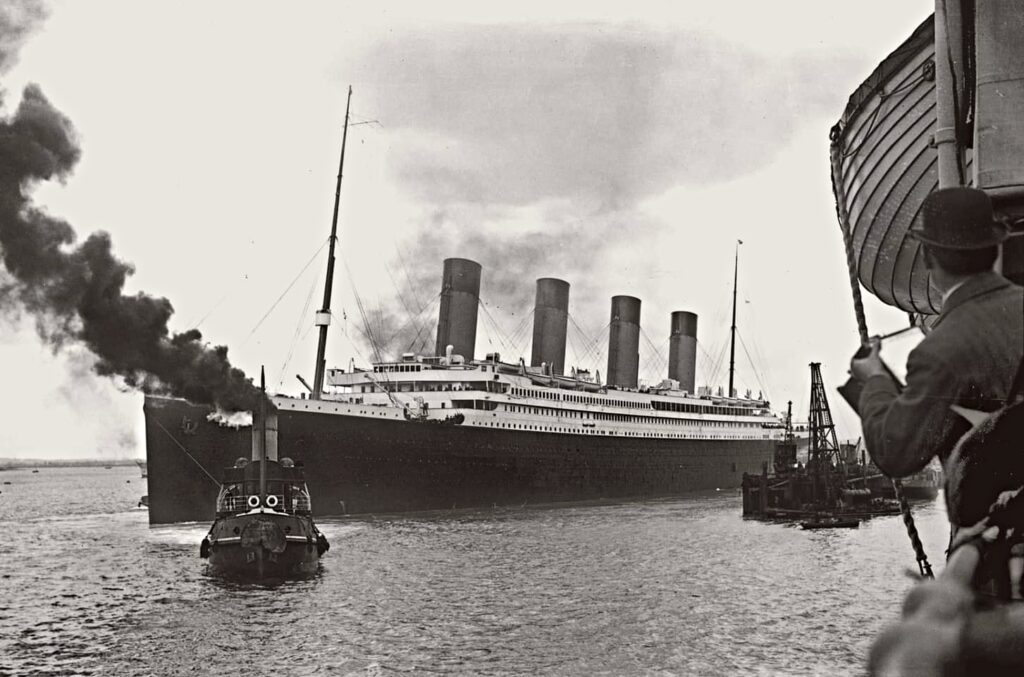

This secret has fascinated humans for centuries: how massive ships, built from materials heavier than water, manage to float rather than sink to ocean depths. From the awe-inspiring grandeur of ocean liners to the robust resilience of cargo ships, the ability of these massive vessels to float gracefully on the water is a marvel of engineering and science. This phenomenon hinges on a concept known as buoyancy. Let’s explore the principles, materials, and technologies that enable ships to float and stay afloat, even in the face of rough seas.

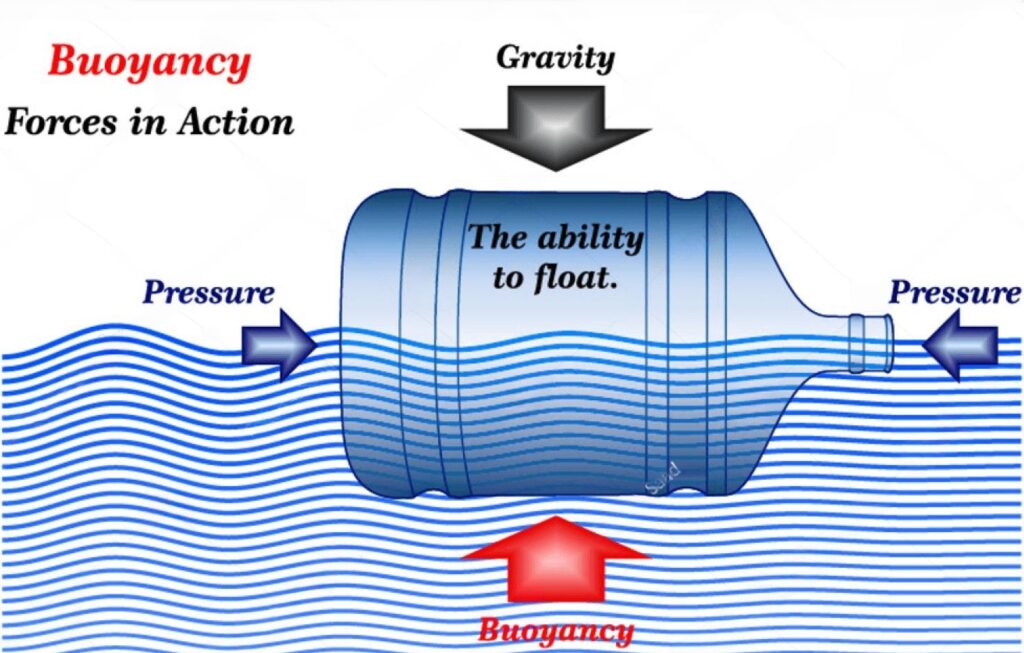

Introduction to Buoyancy

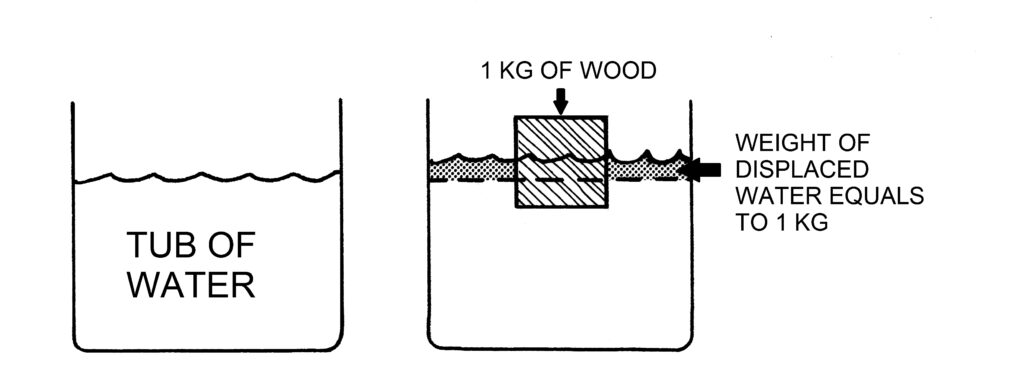

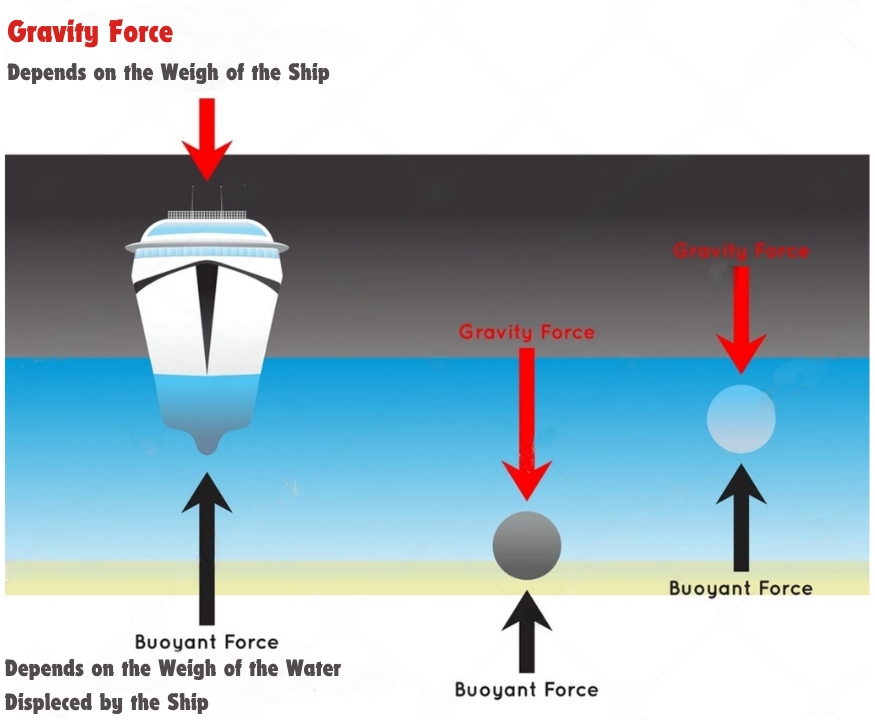

The concept of buoyancy, a key factor in understanding how ships float, dates back to ancient Greece. Archimedes, a Greek mathematician and inventor, discovered that an object immersed in a fluid experiences an upward force equal to the weight of the fluid it displaces. This principle, now known as Archimedes’ principle, forms the foundation of buoyancy. Buoyancy is what allows ships, despite their enormous size and weight, to remain afloat. It’s the upward force exerted by a fluid, counteracting the weight of an object immersed in it. Essentially, it’s a battle of forces where buoyancy must equal or exceed the gravitational pull on an object to keep it afloat.

Now, what is the brain behind this operation? Enter Archimedes’ principle. It states that the buoyant force on a submerged object is equal to the weight of the fluid that the object displaces. Picture a bathtub: when you step in, the water rises. What you’re witnessing is your own personal Archimedes’ demonstration.

This isn’t just about a bathtub show; it’s a brief history of humanity’s engagement with buoyancy. Reports of Archimedes’ ‘Eureka!’ moment in ancient Greece have echoed throughout time, showcasing our desire to master the seas. Knowledge of buoyancy has not only defined naval architecture but has also been pivotal in trade, exploration, and warfare throughout history.

A ship floats because it displaces a volume of water equal to its own weight. This is known as the principle of displacement. When a ship is placed in water, it pushes water out of the way, creating an upward force that counteracts the weight of the ship. This upward force is what keeps the ship afloat. Imagine this: As a ship sits in the water, it pushes water away, creating a force opposite to gravity. This is why a steel canoe can float while a steel block sinks: it’s all about the displacement.

The Science of Floating

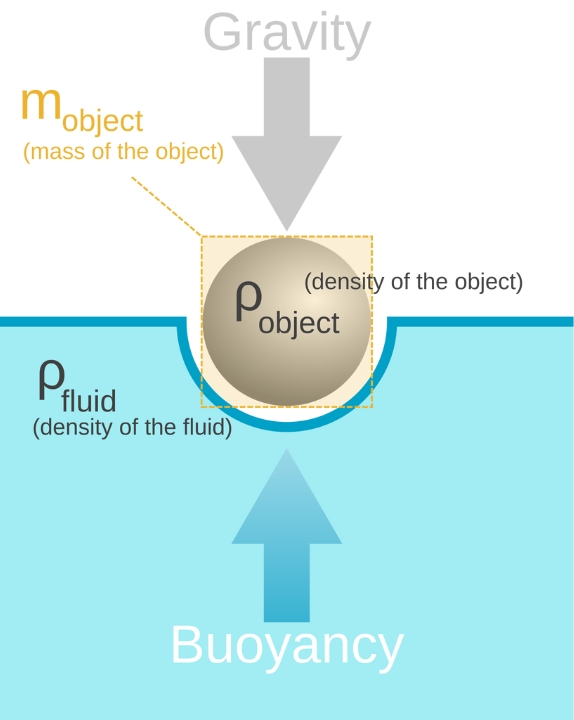

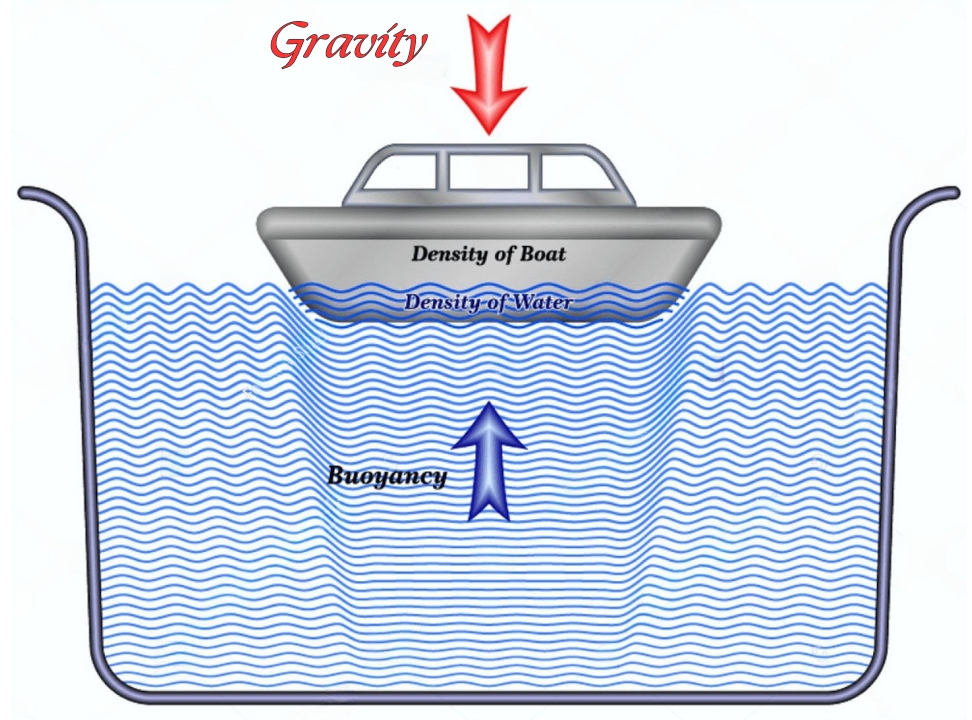

To understand how ships float, it’s essential to grasp the concepts of density and buoyancy. Density is defined as mass per unit volume. When an object is placed in water, it will sink if it is denser than the water and float if it is less dense. Ships are designed to be less dense than the water they displace, which is achieved through careful engineering and design.

Density is simply how much stuff is packed into a given volume. Think of a sponge compared to a rock: Both might be the same size, but the rock has far more mass, making it denser and more likely to sink.

The difference between the density of water and the density of a ship is fundamental here. Water has a density of about one gram per cubic centimeter. Ships are designed to be less dense as a whole, taking into account the air trapped inside, which means that they can float despite being made of materials that are individually denser than water.

How does shape factor into this? Well, the shape of a ship serves a greater purpose than just looking good. It actually affects its buoyancy significantly. A wide, bottom-heavy shape allows a ship to displace enough water to support its weight. The shape of the ship plays a crucial role in its buoyancy. A ship’s hull is designed to displace a sufficient amount of water to counteract the weight of the ship. The more water a ship displaces, the greater the buoyant force acting upon it. This is why ships have wide, flat bottoms and why their hulls are often large and voluminous.

Bernoulli’s Principle Relation to Floating Ships

Bernoulli’s principle, named after the Swiss mathematician and physicist Daniel Bernoulli, is often used to explain various phenomena in fluid mechanics, such as the lift on an airplane wing. Bernoulli’s principle is not directly related to the buoyancy that allows ships to float. The flotation of ships is primarily explained by Archimedes’ principle, which deals with the buoyant force exerted by a fluid on an immersed object. Archimedes’ principle states that any object completely or partially submerged in a fluid (liquid or gas) experiences an upward force, called buoyant force, which is equal to the weight of the fluid that the object displaces.

However, Bernoulli’s principle can have some applications in the context of ships and marine engineering, particularly in the design of hulls and sails. For instance:

Hull Design: The shape of a ship’s hull can be optimized to reduce drag and improve stability, which involves considerations of fluid flow around the hull. Bernoulli’s principle helps in understanding how varying flow velocities around the hull can affect pressure and thus influence the ship’s movement and stability.

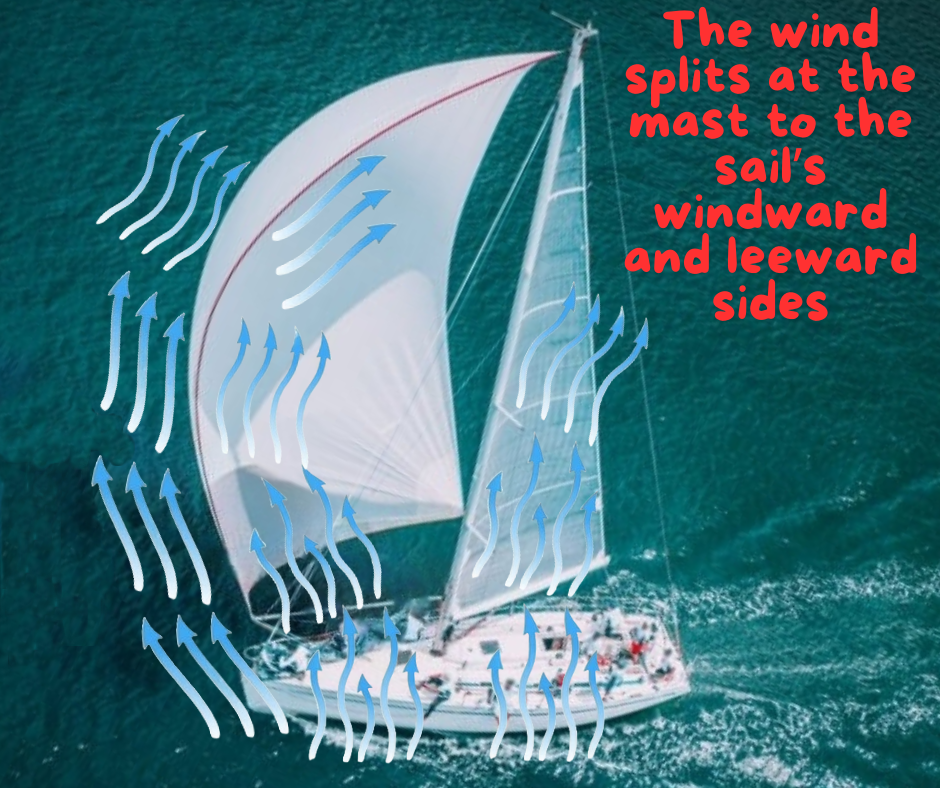

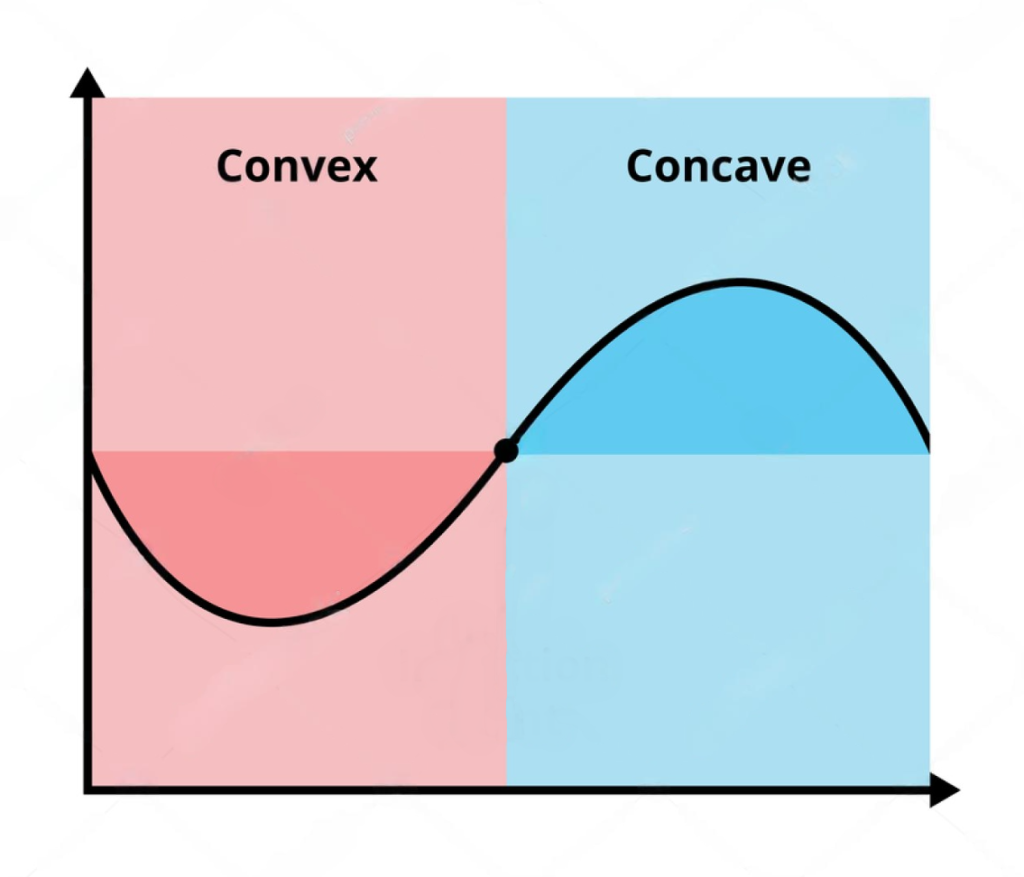

Sailboats: In sailboats, Bernoulli’s principle is crucial for understanding how sails generate lift. The shape of the sails and the wind flowing over them can create a pressure difference, propelling the boat forward. The air moving faster over the convex side of the sail creates lower pressure compared to the concave side, resulting in lift, similar to an airplane wing.

In summary, while Bernoulli’s principle is not the primary explanation for why ships float, it plays a significant role in other aspects of ship design and marine dynamics, particularly those involving fluid flow and pressure differences.

Crafting Titans: The Innovations in Shipbuilding Materials

Shipbuilding materials are chosen for their unique blend of strength, durability, and, importantly, weight. After all, the goal is not only to construct a vessel that can withstand the seas but also to ensure that it can float effectively. Now, the materials used in today’s shipbuilding are impressive. They need to be strong enough to resist the relentless force of oceans and yet remain light enough to maintain buoyancy. That’s where materials like steel, aluminum, and composite materials come into the picture. It’s the workhorse of shipbuilding, prized for its resilience and ability to shape into watertight structures. Steel is favored for its strength and durability. Aluminum is lighter than steel, although less sturdy, it plays a critical role in situations where weight saving is paramount. Composites, on the other hand, are making waves for being not just lightweight but also resistant to corrosion, a big plus for any sea-going vessel. Composite materials, which combine the best properties of different substances, are increasingly used in modern shipbuilding.

Click to expand all the images. For high resolution and full size images you may also right click and open in new tab or window.

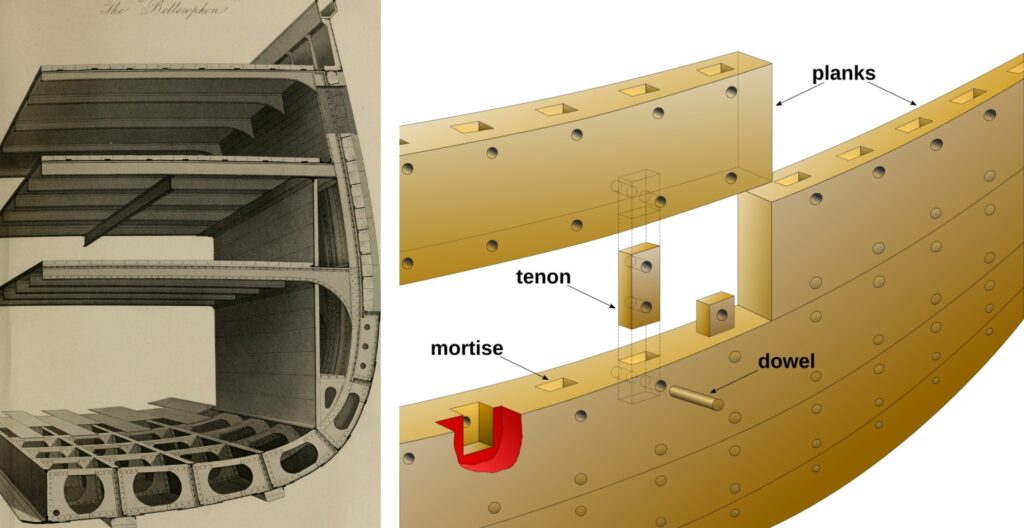

Left: Excerpt from book “Shipbuilding In Iron And Steel: A Practical Treatise…” by Edward James Reed. Year 1869

Right: Principle of assembling planks of the antic Greek vessels by mortise and tenon joint strengthened with dowels, probably used in the construction of the hulls of the triremes. Period : Used since the Homeric times. Reference : Jean Taillardat

The reason these materials are the backbone of the maritime industry is because they’re reliably consistent. Steel’s strength ensures that it remains structurally sound against high waves and potential impacts. Durability means less wear and tear despite constant exposure to harsh marine environments. Weight is key because it affects the amount of water a ship displays and, therefore, its ability to float. Each material brings its inherent advantages to the table, balancing these three factors to meet the demands of modern shipbuilding.

Steel and aluminum, despite being heavier than water, contribute to the overall buoyancy of the ship through their distribution within the hull’s structure. The hull’s design ensures that the ship displaces enough water to support the weight of the materials and everything on board.

The Architectural Marvel of Ship Hulls: Crafting Stability on the Seas

The choice of material works in tandem with hull design. This isn’t just about steel meeting water; it’s also about how that steel is shaped and formed. Different types of hulls, from the bulbous bow to the flat-bottomed barge, are each specially engineered to fulfill their purpose and keep the ship not only afloat but stable and efficient through the water.

The hull is the watertight body of the ship, and its design is crucial for buoyancy and stability. Hulls are designed to maximize the amount of water displaced while minimizing resistance as the ship moves through the water. There are different types of hulls, each suited to specific purposes:

Displacement Hulls: These hulls are designed to displace water equal to their weight. They are typically used in large, heavy vessels such as cargo ships and tankers. Displacement hulls provide stability and are efficient at low speeds.

Author: U.S. Army Corps of Engineers Detroit District

Planing Hulls: These hulls are designed to lift the ship out of the water at high speeds, reducing resistance and allowing for faster travel. They are commonly used in smaller, high-speed boats.

The design of the hull is a delicate balance between stability, buoyancy, and speed. The shape and size of the hull determine how much water the ship can displace, and therefore how much weight it can carry.

Take a minute to imagine slicing a ship lengthwise; you’d be staring at the cross-section of a hull. Now, hulls aren’t a one-size-fits-all deal. They’re meticulously crafted based on the ship’s intended use and the waters it’s navigating. You’ve got displacement hulls, with their classic U-shape, found on large vessels like cargo ships and tankers that push water aside and are champions of the high seas. Then there’s the V-shape of planing hulls loved by speedboats which allow for gliding over the water at high speeds.

Ballast and Stability

It’s not by accident that ships don’t keel over and sink; it’s by design, and the shape of the hull is critical in this equation. Ballast is used to improve the stability of a ship. Traditionally, ballast consisted of heavy materials such as rocks or sand placed in the bottom of the ship to lower its center of gravity and enhance stability. Modern ships use ballast tanks that can be filled with water to adjust the ship’s buoyancy and stability dynamically.

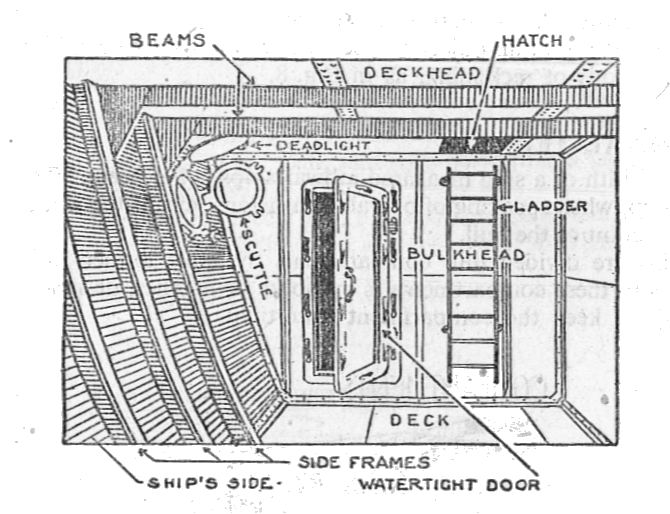

Parts of a water-tight compartment (Seaman’s Pocket-Book, 1943). Source: Scan from by Authority of the Lords Commissioners of the Admiralty (June 1943). Right click to open in new tab or new window for full size image.

Ballast tanks are strategically placed throughout the ship, allowing for precise control over the ship’s stability. By filling or emptying these tanks, a ship’s crew can adjust the weight distribution and buoyancy to suit different conditions. This is particularly important for cargo ships, which may have varying loads that can affect stability.

Weight distribution is critical for maintaining stability. If a ship’s weight is not evenly distributed, it can lead to instability and an increased risk of capsizing. Shipbuilders carefully design the interior of ships to ensure that weight is evenly distributed, and modern ships are equipped with sophisticated systems to monitor and adjust weight distribution as needed. This is how the cargo is stowed. Stashing heavy items willy-nilly within the hold can lead to an unstable ship, and that’s asking for trouble. So, ships have meticulously planned loading strategies to ensure that the weight is evenly distributed, aiding in both buoyancy and stability. This is where involving ballast and watertight compartments becomes super important.

Watertight Compartments

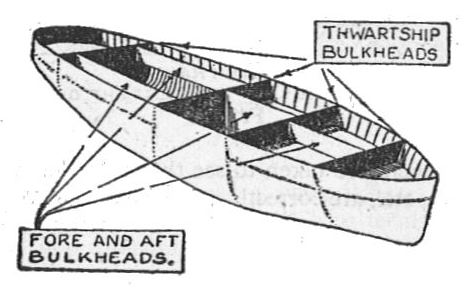

Watertight compartments are another essential feature in modern ship design. These compartments are sections of the ship that are sealed off from one another, preventing water from spreading throughout the ship in the event of a hull breach. The use of watertight compartments can significantly reduce the risk of sinking.

If one compartment is breached and begins to fill with water, the other compartments remain sealed and buoyant, keeping the ship afloat. This principle was famously applied in the design of the RMS Titanic, although the ship ultimately sank because too many compartments were breached.

Safety Features

Modern ships are equipped with numerous safety features to prevent sinking. Bulkheads, which are vertical partitions dividing the ship into compartments, are designed to be watertight and fire-resistant. Lifeboats and emergency procedures are standard on all passenger ships, ensuring that in the event of an emergency, passengers and crew can safely evacuate.

Left: The hull of a minesweeping trawler being constructed using traditional techniques in a shipyard on the east coast of Britain, October 1942. Author: Davies, F A (Lt), Royal Navy official photographer. Source: Imperial War Museum

Right: Putting final touches on a boat hull, Center for Wooden Boats, Seattle, Washington 30 June 2007. Author: Joe Mabel.

Lessons learned from historical shipwrecks, such as the Titanic, have led to significant advancements in ship safety. The Titanic’s sinking highlighted the need for more lifeboats, better communication systems, and more rigorous safety standards. Today, ships must comply with international safety regulations to ensure the highest level of safety for passengers and crew.

Navigating the Future: The Journey of Buoyancy in Maritime Endeavors

The ability of ships to float and not sink is a testament to human ingenuity and the application of scientific principles. Through a combination of buoyancy, careful design, advanced materials, and sophisticated technologies, modern ships are capable of navigating the world’s oceans with remarkable efficiency and safety.

As we look to the future, continued advancements in ship design and technology promise to enhance our understanding of buoyancy and stability even further. These innovations will lead to safer, more efficient ships that can carry more cargo, travel farther, and operate more sustainably.

In conclusion, the science of floating is a fascinating and complex field that underpins one of humanity’s most essential modes of transportation. By understanding and applying the principles of buoyancy, we can continue to explore and connect the world through the vast and open seas. Fair Winds!